CT-500A CNC

CNC Turning Lathes

Модель:

CT-500A CNC

Расстояние по центру:

750/1000/1500mm

Перевернутая кровать:

Φ500 mm

Скорость вращения шпинделя:

100-2000 rpm

отверстие шпинделя:

Φ80 mm

Techmax CT-series CNC lathe (Economic value model) is designed to provide stable performance and high profit. Free to choose single workpiece processing or working with bar feeder to do machining automatically and continuously

CNC SystemFANUC, SIEMENS, FAGOR, MITSUBISHI, GSK cnc controllers are available according to personal habits. | ||

Hydraulic Chuck (Option)3-jaw manual chuck or Taiwan hydraulic chuck(option) is available. This 3-Jaw hydraulic chuck provides excellent workholding capacity. It features industry-standard serrated jaws, and including all necessary adapters and tooling required for installation and operation. |

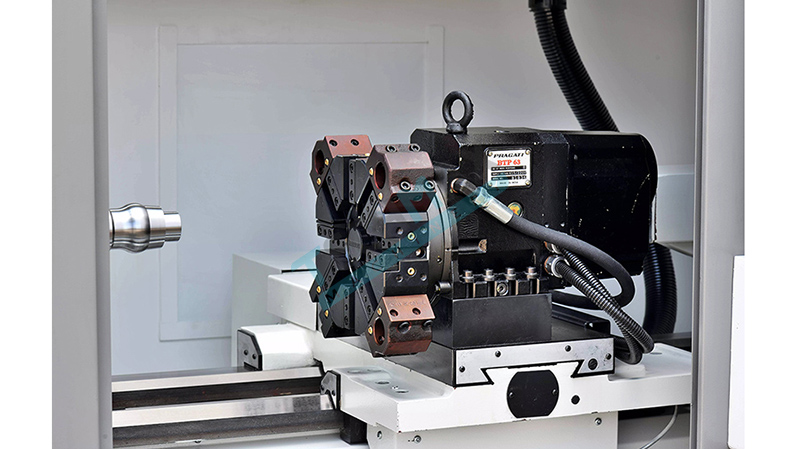

TurretsHigh productivity due the 4-way automatic tool changer as standard. 6-station/8-station tool changer (option) are available, which provides super-rigid mounting of turning tools and boring bars. | ||

Hydraulic Tailstock (Option)Auto chip conveyor (option) is available to remove the chips from the machine quickly. The conveyor can be activated via M-code, or directly from the control pendant, and there are settings to control the interval and duration of the conveyor cycle for automatic operation. | ||

High Rigid TailstockThe tailstock, made of top quality, has a rigid construction, vibration absorbing and can easily travel along the bed guideways. A lead screw, driven by hand wheel, allows axial movement of the quill on a 120 mm maximum travel. It can be set eccentrically with max. ±13 mm for cutting. | ||

Auto Bar Feeder (Option)Free to choose single workpiece processing or working with auto bar feeder to do machining automatically and continuously. Convenient parameters setting without need of any program modification. Length of remnant can be set as desired. Self detection for abnormal motions and is displayed on LCD. | ||

Model | CT-400A CNC | CT-460A CNC | CT-500A CNC |

CAPACITY: | |||

Swing over bed | Φ400 mm | Φ460 mm | Φ500 mm |

Swing over cross slide | Φ210 mm | Φ240 mm | Φ280 mm |

Distance between centers | 750 / 1000 / 1500 mm | 750/1000/1500 mm | 750/1000/1500 mm |

Max. turning length | 600 / 850 / 1350 mm | 600/850/1350 mm | 600/850/1350 mm |

6-station turret max. turning length | 430 / 680 / 1180 mm | 430/680/1180 mm | 430/680/1180 mm |

6-station turret max. turning diameter | Φ295 mm | Φ340 mm | Φ340 mm |

Manual chuck dia. | 8" (200); 10" (250); 12" (305) /(mm) | 8" (200); 10" (250); 12" (305) /(mm) | 8" (200); 10" (250); 12" (305) /(mm) |

Hydraulic chuck dia. | 8" (200); 10" (250); 12" (305) /(mm) | 8" (200); 10" (250); 12" (305) /(mm) | 8" (200); 10" (250); 12" (305) /(mm) |

TRAVEL: | |||

Cross slide travel (X-axis) | 250 mm | 280 mm | 280 mm |

when using stationary cutting blocks | 320 mm | 320 mm | 320 mm |

Longitudinal travel (Z-axis) | 710 / 960 / 1460 mm | 710/960/1460 mm | 710/960/1460 mm |

X/Z-axis guide rails | sliding type | sliding type | sliding type |

X/Z-axis ball screw dia. × thread pitch. accuracy class | Φ25×4 / Φ40×6 mm | Φ25×4/Φ40×6 mm | Φ25×4/Φ40×6 mm |

SPINDLE: | |||

Spindle speed | 100-2000 rpm | 100-2000 rpm | 100-2000 rpm |

Spindle taper | D8 / МK-7 | D8/МK-7 | D8/МK-7 |

Spindle bore | Φ80 mm | Φ80 mm | Φ80 mm |

Hole diameter (Hydraulic chuck) | Φ52; 75; 91 mm | Φ52; 75; 91 mm | Φ52; 75; 91 mm |

Draw pipe inner diameter (Hydraulic chuck) | Φ52; 75 (option) mm | Φ52; 75 (option) mm | Φ52; 75 (option) mm |

Max. bar diameter (hydraulic chuck) | Φ48; 63 (option) mm | Φ48; 63 (option) mm | Φ48; 63 (option) mm |

TOOL: | |||

Tool station number | 4; 6; 8 pcs | 4; 6; 8 pcs | 4; 6; 8 pcs |

Tool section size | 25×25; 20×20 (6 station BWD) mm | 25×25; 20×20 (6 station BWD) mm | 25×25; 20×20 (6 station BWD) mm |

Max. tool diameter | Φ20 (6 station BWD) mm | Φ20 (6 station BWD) mm | Φ20 (6 station BWD) mm |

TAIL STOCK: | |||

Tailstock quill taper | MK-4 | MK-5 | MK-5 |

Tailstock quill diameter | Φ75 mm | Φ75 mm | Φ75 mm |

Tailstock quill travel | 130 mm | 130 mm | 130 mm |

ACCURACY: | |||

Positioning accuracy | ±0.016 mm | ±0.016 mm | ±0.016 mm |

Repeatability | ±0.009 mm | ±0.009 mm | ±0.009 mm |

SPEED: | |||

X/Z-axis rapid traverse | 8 / 10 m/min | 8/10 m/min | 8/10 m/min |

COOLANT: | |||

Coolant pump power | 0.09 kw | 0.09 kw | 0.09 kw |

Hydraulic station power | 0.75 kw | 0.75 kw | 0.75 kw |

POWER: | |||

Main motor power | 5.5; 7.5 kw | 5.5; 7.5 kw | 5.5; 7.5 kw |

Main motor torque | 57; 76 N.m | 57; 76 N.m | 57; 76 N.m |

Spindle torque | 142; 190 N.m | 142; 190 N.m | 142; 190 N.m |

Max. torque on the spindle | 450 N.m | 450 N.m | 450 N.m |

DIMENSIONS: | |||

Overall dimensions (L×W×H) | 2060 / 2310 / 2790×1345×1600 mm | 2060/2310/2790×1345×1600 mm | 2060 / 2310 / 2790×1345×1600 mm |

Weight approx. | 2170 / 2250 / 2800 kg | 2200 / 2350 / 2900 kg | 2200 / 2350 / 2900 kg |

▪ Siemens 808D controller

▪ Siemens controller with a MPG unit for lathe setting

▪ 4-position automatic tool post

▪ 80mm spindle bore

▪ Infinitely variable spindle speed by inverter

▪ 3 jaw chuck - 200mm

▪ Step less speed change throughout entire speed range

▪ Alarm Lamp (3 color status light)

▪ Manual tail stock

▪ Coolant and lubrication system

▪ Heat exchanger for electrical cabinet

▪ LED Work light

▪ Dead Centre

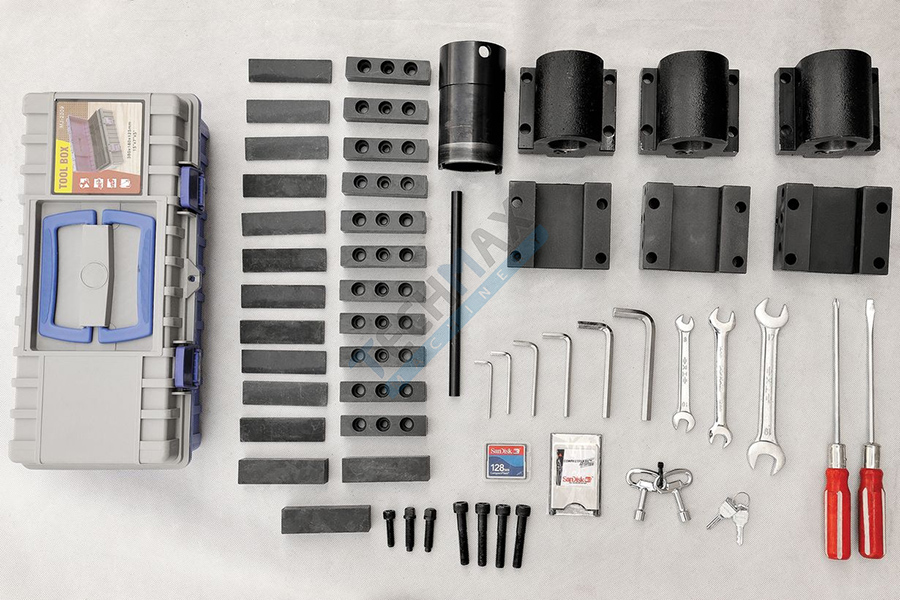

▪ Maintenance tool kit

▪ CNC system Fanuc 0i TF / Siemens 828D

▪ Shop Turn for Siemens 828D CNC system

▪ 6-8 position tool post

▪ 3-jaw hydraulic chuck - 8/ 10/12 inches

▪ Hydraulic tailstock

▪ Fully enclosed cover

▪ Bar puller

▪ Chip conveyor and a chip cart

▪ Other configuration changes are possible as agreed with the client

<< Предыдущий!

Следующий >>